CRC 3-36 Multi Purpose Lubricant

Product Details:

- Product Type other

- Product Form Spray

- Shape Round

- Application Other

- Click to View more

CRC 3-36 Multi Purpose Lubricant Price And Quantity

- 48 Piece

- 650 INR/Piece

CRC 3-36 Multi Purpose Lubricant Product Specifications

- Other

- other

- Spray

- Round

CRC 3-36 Multi Purpose Lubricant Trade Information

- Surat

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 100 Piece Per Day

- 1 Days

- If order is confirmed we will reimburse the sample cost

- Central America Australia South America Western Europe Middle East Asia Eastern Europe North America Africa

Product Description

CRC 3-36 Multi Purpose Lubricant

GENERAL DESCRIPTION

Multi-purpose lubricant and corrosion inhibitor.

CRC 3-36 Multi Purpose Lubricant is based on a paraffinic oil and a multiple organic

inhibitor system that prevents rust and corrosion by displacing and sealing out moisture

and by forming a continuous protection barrier against water and oxygen. The oily,

almost invisible film of CRC 3-36 lubricates and penetrates into the finest pores.

CRC 3-36 effectiveness for surface protection is derived from three of its principal properties :

affinity for metal

low surface tension

high capillary action.

By its affinity for metal and low surface tension CRC 3-36 displaces moisture

and separates it from contact with the metal surface. The high capillary action

contributes to the great spreading power.

FEATURES

Multi-purpose lubricant, penetrant and corrosion inhibitor

Displaces and seals out moisture, especially after washing or hosing off engines or equipment

Penetrates through corrosion to loosen frozen parts

Lubricates without leaving a sticky residue

Cleans light soils and contaminants

Prevents 'fingerprinting' by its protective film

Protection of all metals and alloys

Compatible with most painted surfaces, coatings, plastics and rubbers

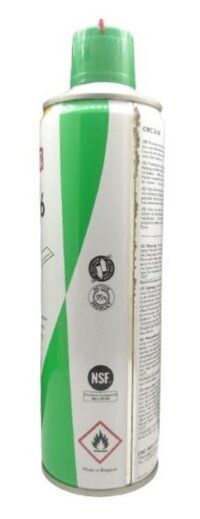

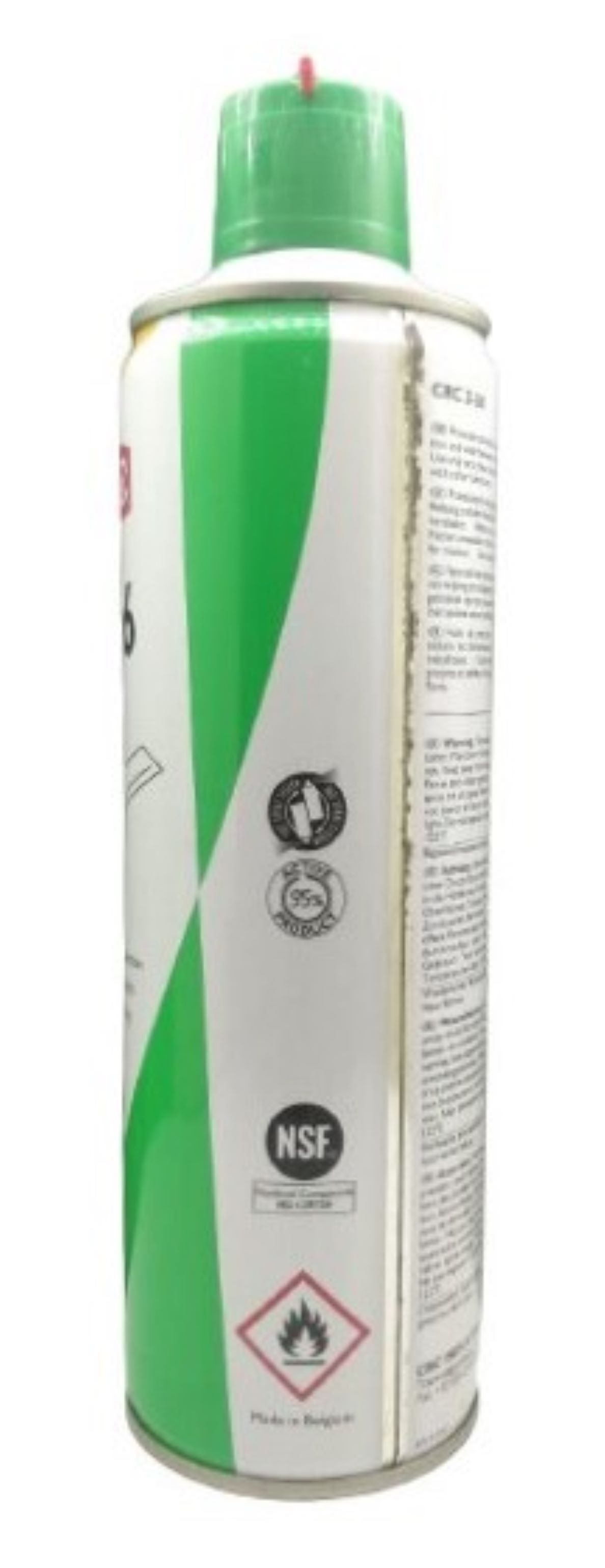

Equipped with the 360 (upside-down) spray valve for added convenience

Pressurised with non-flammable CO2 propellant

Active product content of 97%

Specifications :

NSN 6850-00-050-0659

USDA class H2

APPLICATIONS

For new, in service or stored equipment.

PROCESS MANUFACTURING :

Heat treated parts

Machined surfaces

Finished welds

In-process aluminium extrusions

Precision mechanisms

MACHINING :

Fixtures

Dies

MATERIAL STORAGE

Tubings

Castings

Gears

Weld rod and wire

MAINTENANCE

Air actuated tools

Conveyors

Frozen joints

Locks

Hoists

DIRECTIONS

Spray in light, even films to lubricate and protect metal surfaces. For electrostatic spraying, addition of polar solvents (butanol, nitropropane) may be necessary.

Apply liberally and allow to penetrate to free rusted parts. Full penetration may require several hours.

To displace moisture, spray wet surfaces until run-off is clear and moisture-free.

To be removed by solvent cleaners (CRC Industrial Degreaser, CRC Fast Dry Degreaser) or alkaline degreasing before surface treatment.

For application of CRC 3-36 in dipping baths, customers should take care to stir

from time to time (to distribute small amounts of deposits) and to prevent excessive

evaporation of solvent. When stable emulsions have been formed, the bath should be emptied and cleaned, and the product replaced.

Do not use on energized equipment. Use in a well ventilated area.

A safety data sheet (MSDS) according EU-Directive 93/112 is available for all CRC products.

TYPICAL PRODUCT DATA (without propellant)

Appearance : blue-green, clear

Specific gravity (20C) : 0.83

Distillation range of solvents : 190-250C

Freezing point : -50C

Flash point (open cup) : 78C

Dynamic viscosity (20C) : 3.9 m Pa. s

Ultimate film thickness : 2.10-6m,( 20C, after a 24 hr spread)

Maximum expected coverage : 100 m2/l, (C, after a 24 hr spread)

Other Products in 'CRC Cleaning Spray' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |