CRC SP-400 Wax Based Aniti Rust Coating

Product Details:

- Product Type Aerosol Cans

- Product Form Spray

- Shape Round

- Click to View more

CRC SP-400 Wax Based Aniti Rust Coating Price And Quantity

- 980 INR/Piece

- 12

- 150.00 - 500.00 INR/Piece

CRC SP-400 Wax Based Aniti Rust Coating Product Specifications

- Round

- Spray

- Aerosol Cans

CRC SP-400 Wax Based Aniti Rust Coating Trade Information

- Cash Against Delivery (CAD) Cheque Cash Advance (CA) Cash in Advance (CID)

- 5000 Per Week

- Days

- If order is confirmed we will reimburse the sample cost

- Middle East Asia Africa

Product Description

1. GENERAL DESCRIPTION

Long-term outdoor and indoor corrosion inhibitor. CRC SP 400 ANTI

RUST COATING is a long-term, outdoor and indoor corrosion inhibitor for

machined surfaces and assemblies subjected to long periods of storage or adverse

shipping conditions. the amber, dry, waxy film never becomes brittle and is highly resistant

to humidity and severe corrosive atmospheres.

2. FEATURES

Long-term protection (up to 1 year outdoors) for all metals during shipment or extended storage

Waxy film seals out moisture effectively

Highly resistant to humidity and salt spray

Can be removed or diluted, for film thickness variation, with petroleum solvents

Aerosols use hydrocarbon propellant for controlled application and film thickness

Specifications :

meets Mil-C-16173, grade 4

NSN 8030-17-039-7214

USDA, class P1

3. APPLICATIONS

Protection of finished components, in-process parts, in-transit goods, raw materials, structural steel.

Effective corrosion shield for overseas shipments, winterising of farm machinery, outdoor storage.

Protection of equipment, tools, dies, molds, jigs, pipes, shafts, housings, wire ropes, valves, gears.

To be used for brine and chloride resistance in refrigeration plants.

In paper and pulp plants.

As a cable end sealer and pipe joint protector in utilities .

Protection of air conditioning and electrical equipment in hospitals and educational institutions.

In airport and aircraft maintenance and construction.

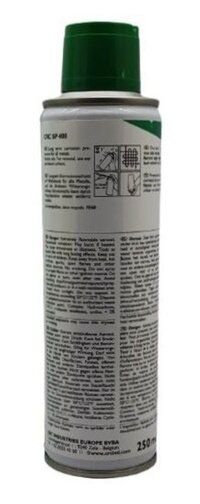

4. DIRECTIONS

Shake aerosol can well before use. Stir or mix bulk product to break its paraffin

structure before dipping or brushing applications.

Mask area not to be treated. If necessary, remove by solvent cleaners

(CRC Fast Dry Degreaser, CRC Industrial Degreaser)

Film thickness may be adjusted by thinning with petroleum solvents,

but corrosion resistance varies with film thickness (see typical properties)

For applications in wet or very humid conditions, CRC 3-36 should be

applied first for complete moisture displacement. Allow then 2 to 4 hours

for solvent evaporation before SP 400 is applied.

When finished spraying, clean aerosol valve by turning can

upside down and pressing actuator until only propellant escapes.

Do not use on energised equipment. Use in well ventilated areas.

A Safety data sheet (MSDS) according EU directive 93/112 is

available for all CRC products.

5. TYPICAL PRODUCT DATA (without propellant)

Appearance : amber, waxy

Specific gravity ( 20C)

aerosol : 0.87

bulk : 0.92

Distillation range of solvents

aerosol : 50-230C

bulk : 160-230C

Flash point (closed cup)

aerosol : 0C

bulk : 35C

Dynamic viscosity (20C)

aerosol : 58, 5 Ps

bulk : 200 to 700 mP a. s depending on paraffin structure

Freezing point

aerosol : - 30C

bulk : -12C

Coverage

spraying : 20 m2L

dipping : 5 m2L

Solvent dissipation ( 20C, thin film) : 1-2 h.

Film properties (after evaporation of solvent)

Film appearance : dry, waxy

Film thickness : 10 - 50

Salt spray resistance (ASTM B 117)

10 film thickness : 200 h.

50 film thickness :500 h.

Auto-ignition temperature :250C

Flow resistance (vertical) :80C

6. PACKAGING

aerosol : 12 x 300 ml

bulk : 4 x 5 L 20 L 200 L

Other Products in 'CRC Cleaning Spray' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |