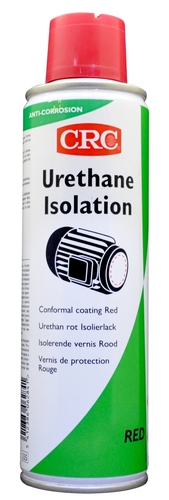

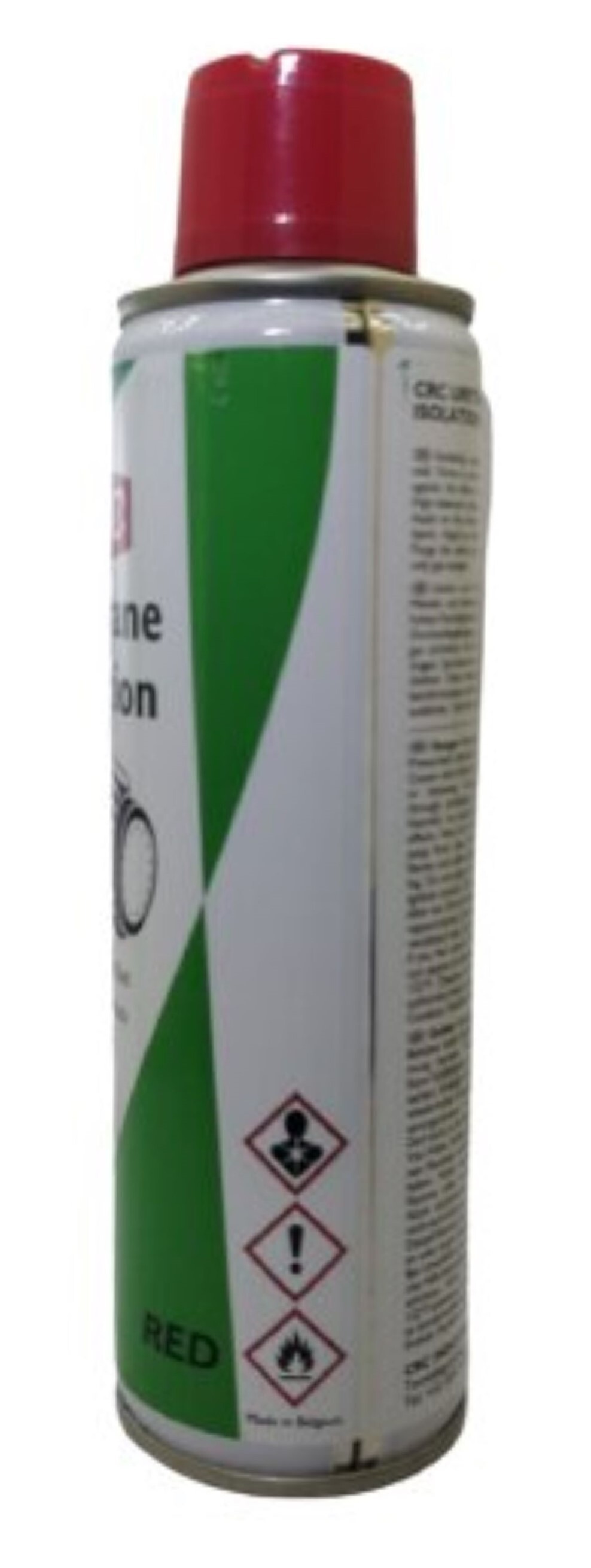

Crc Urethane Isolation Red Insulating Varnish Spray

Product Details:

- Product Type Aerosol Cans

- Product Form Spray

- Shape Round

- Application Other

- Click to View more

Crc Urethane Isolation Red Insulating Varnish Spray Price And Quantity

- 500.00 - 800.00 INR/Bottle

- 48 Piece

- 650 INR/Bottle

Crc Urethane Isolation Red Insulating Varnish Spray Product Specifications

- Other

- Spray

- Aerosol Cans

- Round

Crc Urethane Isolation Red Insulating Varnish Spray Trade Information

- Surat

- 500 Piece Per Day

- 1 Days

- If order is confirmed we will reimburse the sample cost

- South America Western Europe Central America Australia North America Eastern Europe Middle East Asia Africa

Product Description

Crc Urethane Isolation Red Insulating Varnish Spray

GENERAL DESCRIPTION

Clear or red one-component urethane type conformal coatings. CRC Urethane

Coats provides an air curing conformal urethane type coating that insulates electrical

Electronic equipment, seals out water and moisture and acts as a barrier for contaminants.

CRC Urethane Coats dry fast and adhere well. After curing they form a highly flexible

film which is durable and resistant to abrasion and contaminants.

FEATURES

Available in clear or red formulations :

Clear : contains U.V.- fluorescent dye for easier quality control

Red : provides additional corrosion resistance

Dries quickly to a durable, Flexible and non- conductive film

Excellent electrical characteristics :

High dielectric strength

High surface and volume resistivity

Low dielectric constant

Low dissipation factor

Effective temperature range of - 40C to + 120C

Abrasion-resistant insulator for electrical/electronic equipment and components.

Specifications :

NSN 5970-01-017-5738

USDA-Red Urethane is classified P1

APPLICATIONS

Urethane Clear - protective coating for :

Printed circuit boards

Urethane Red or Clear - coating for :

Electric motor windings

Armature coils

Boxes

Controls

Commutator ends

Terminals

Housings

Transformer connectors

Bus bars

Solenoids

Tools.

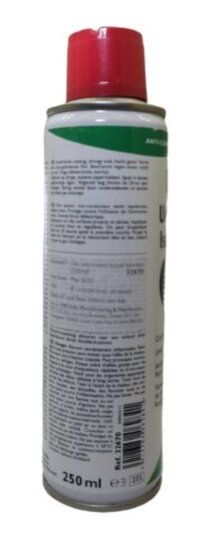

DIRECTIONS

Clean and degrease surface thoroughly before application (use one of the CRC precision

cleaners or Lectra Clean as appropriate).

Shake aerosol can well; red formulation contains an agitator ball for pigment dispersion.

Stir or mix bulk product to homogenize. Repeat while using. Petroleum solvents (white spirit,...)

may be used to dilute the bulk product to the required viscosity and film thickness.

Apply in light, even coats. Best results are obtained with 2 (or even more) lighter rather than 1 heavy coat.

Additional coats can be applied when first coat is dry (20-25 min.). For maximum adhesion,

2nd coat must be applied within 48 hours.

Due to slow cross linking reaction, room temperature curing takes over 1 week to obtain final film hardness.

However, cured for handling is already reached in 1 day.

Accelerated curing can be accomplished by baking up to 80C. Total curing thus takes only 8 to 12 hours,

increasing final hardness and chemical resistance of film .Cured for handling is reached in 2 to 3 hours.

For dipping applications it is advised to cover the bath when not in use and to prevent skin formation

by keeping air out (e.g. by nitrogen blanketing). Rags or filters heavily contaminated with these products should

be protected from auto-ignition by soaking with water or cleaning (e.g. with CRC Lectra Clean).

When finished spraying, clear valve by turning can upside down and pressing button until only propellant

escapes. If clogging occurs, remove button and clean orifices with fine wire.

If necessary remove with CRC Lectra Clean (if curing has only started) or CRC Gasket Remover (for fully cured films).

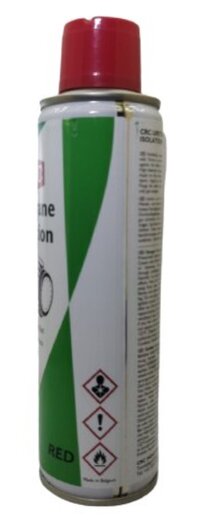

Do not use on energized equipment. Use in well ventilated area.

A safety data sheet (MSDS) according EU directive 93/112 is available for all CRC products.

TYPICAL PRODUCT DATA (without propellant)

Clear Red

Other Products in 'CRC Cleaning Spray' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |