LIFTIT Magnetic lifter 200 Kg

Product Details:

- Weight 5.5 Kilograms (kg)

- Product Type Magnetic Lifter 200 KGS

- Color yellow

- Usage Permanent Magnetic Lifters are mainly used to lift steel plates, blocks, press molds, etc. and load / unload in machines during handling operation. They can hoist moving iron blocks and other magnetic material. They are easy to operate and safe to handle and hence are widely used as lifting devices in factories, docks, warehouses, and transportation industries. By using them, you can improve your working conditions and increase your working efficiency.

- Condition New

- Lifting Capacity 200 Kilograms (kg)

- Max. Lifting Load 200 Kilograms (kg)

- Click to View more

LIFTIT Magnetic lifter 200 Kg Price And Quantity

- 9900.00 - 9900.00 INR/Piece

- 9900 INR/Piece

- 1 Piece

LIFTIT Magnetic lifter 200 Kg Product Specifications

- 1 yers

- 200 Kilograms (kg)

- 5.5 Kilograms (kg)

- New

- Permanent Magnetic Lifters are mainly used to lift steel plates, blocks, press molds, etc. and load / unload in machines during handling operation. They can hoist moving iron blocks and other magnetic material. They are easy to operate and safe to handle and hence are widely used as lifting devices in factories, docks, warehouses, and transportation industries. By using them, you can improve your working conditions and increase your working efficiency.

- 200 Kilograms (kg)

- Manual

- yellow

- Magnetic Lifter 200 KGS

LIFTIT Magnetic lifter 200 Kg Trade Information

- Surat

- 10 Piece Per Day

- 1 Days

- If order is confirmed we will reimburse the sample cost

- Box Packing

- All India

- Test Certificate

Product Description

LIFTIT Permanent Magnetic Lifters are mainly used to lift steel plates, blocks, press molds, etc. and load / unload in machines during handling operation. They can hoist moving iron blocks and other magnetic material. They are easy to operate and safe to handle and hence are widely used as lifting devices in factories, docks, warehouses, and transportation industries. By using them, you can improve your working conditions and increase your working efficiency.

Features

Zero electricity required

Forged hook for high mechanical strength and durability

Precision machined assembly block in a single piece to enhance efficiency

Designed for safety and lightweight

Full proof locking system with an easy to use "on" and" off" lever

3 times rated capacity factor of safety to meet the safety standards as per international standards for under the hook devices

Test certificate for safety factor from government-approved third party

No Maintenance and Operating cost

No damage to the work piece being lifted

Very Compact

Benefits

Lifting Magnets use space more effectively. Eliminates the need to gauge and increase stacking height

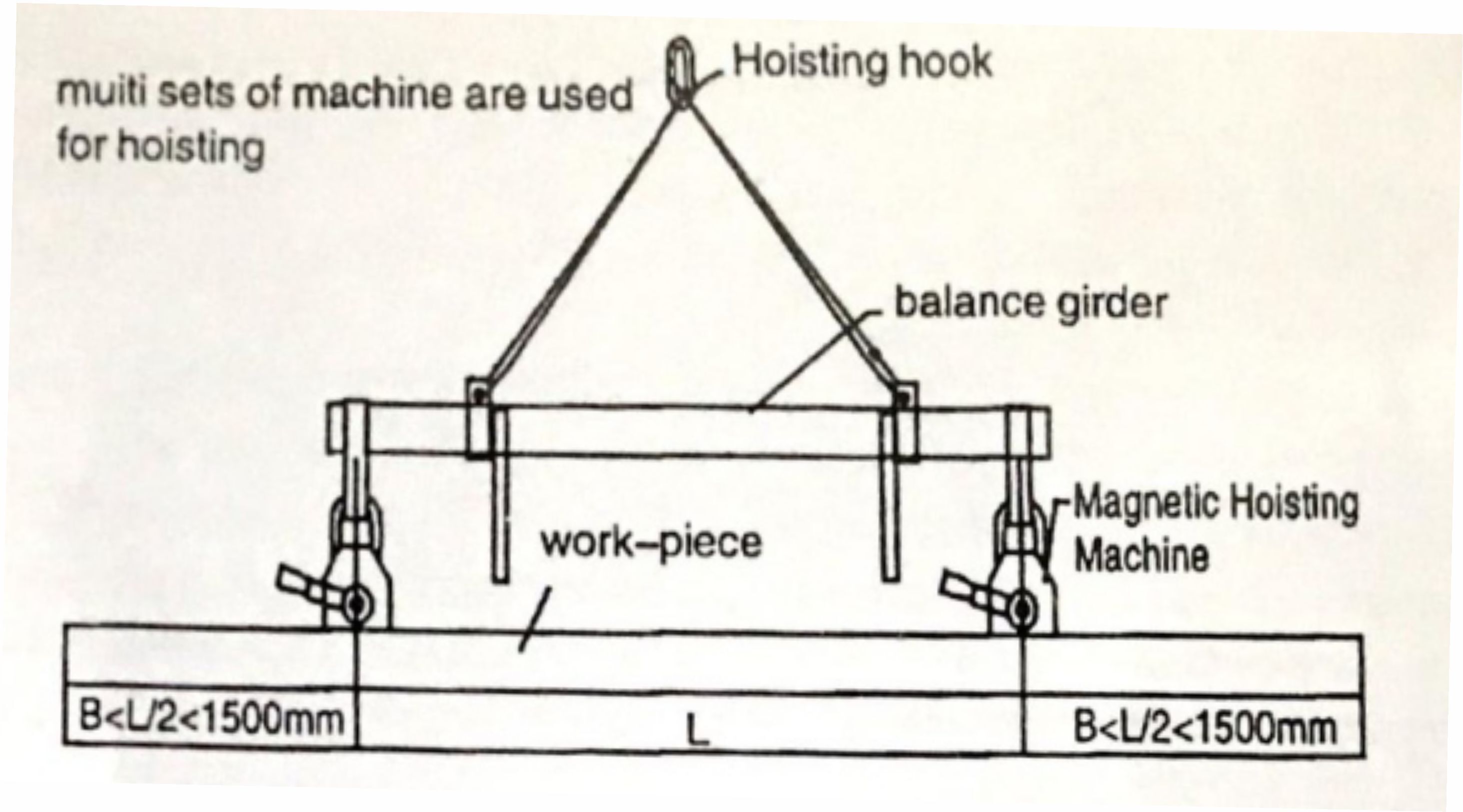

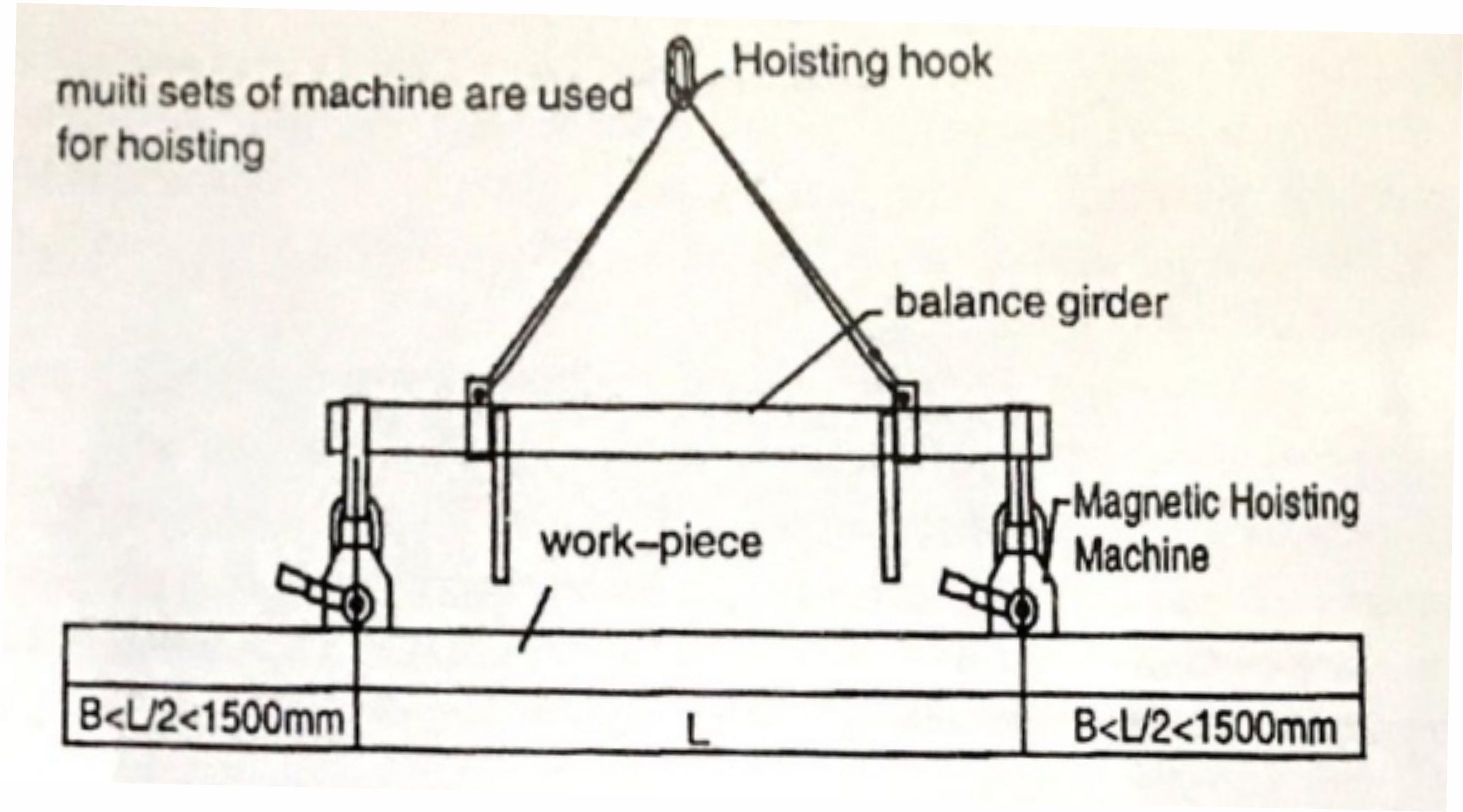

As less as one operator can move large and heavy work-piece safely and easily using Magnetic Lifters

Lifting Magnets save labor and time - improves productivity

Construction

LIFTIT Permanent Magnet Lifters have a strong magnetic field path produced bindermagnetic materials.

"On" and "Off" of the magnetic path is controlled by turning the lever manually.

There are shackles on the top of Magnetic Lifter for lifting.

Operating Instruction

The work piece surface(magnetic ferrous surface) and the magnet pole surface must be clean and smooth to achieve maximum efficiency. Ground and machined surface are ideal but a good clean surface on a ferrous or casting is acceptable provided a sufficiently flat area available for a good magnetic contract with the work piece

There should be no air gap/inclusions between the magnet pole and the job surface

Place the magnet on the ferrous surface. Unlock the lever by pulling it out and then turn it to the ON position. Once it is made ON, lock it by releasing it. For making it OFF, please follow the similar procedure. (Do not place on wooden surface OR non-magnetic surface - it will not be possible to operate Lever to ON position)

Move the load smoothly,avoid shocks and collisions

To place/drop the lifted material, operate the lever to the "OFF position

Safety Instruction

Place the magnet on the Ferrous Surface in the "OFF position and then make it "ON. Do not make it ON without keeping it on a ferrous surface

The magnet is to be placed on the center, i.e. centering to the center of gravity of the load and then lift

While handling the load, no person should be allowed in the immediate danger zone

Ensure that the lever is made "OFF after resting the load at the desired place in the balance position

When Not In Use

Apply Grease / Oil on Magnetic Poles surface to prevent it from rusting and

Place it on a thick wooden plank to safeguard its Magnetic poles from any damages, scratches, etc.

Why LIFTIT Permanent Magnetic Lifters?

LIFTIT magnetic Lifters are ruggedly built

High Lifting Capacity with respect to size & weight

Works without Electrical Power

No maintenance and operational costs

Very easy to use - Save time & energy

Made with high energy rare earth magnets (NdFeB)

Mechanical Switching by turning a lever with a lock

The system against switching off accidentally

No damage to the work piece being lifted

Easily transportable

Reliable

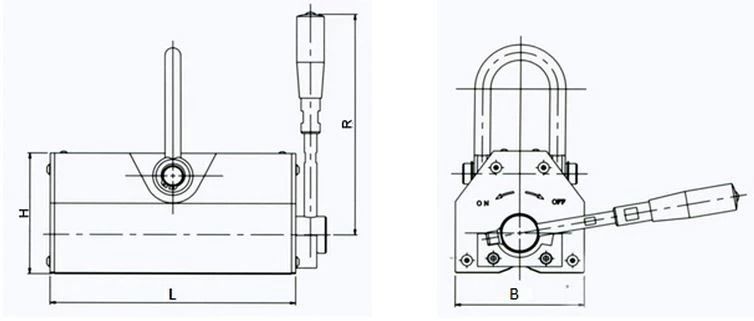

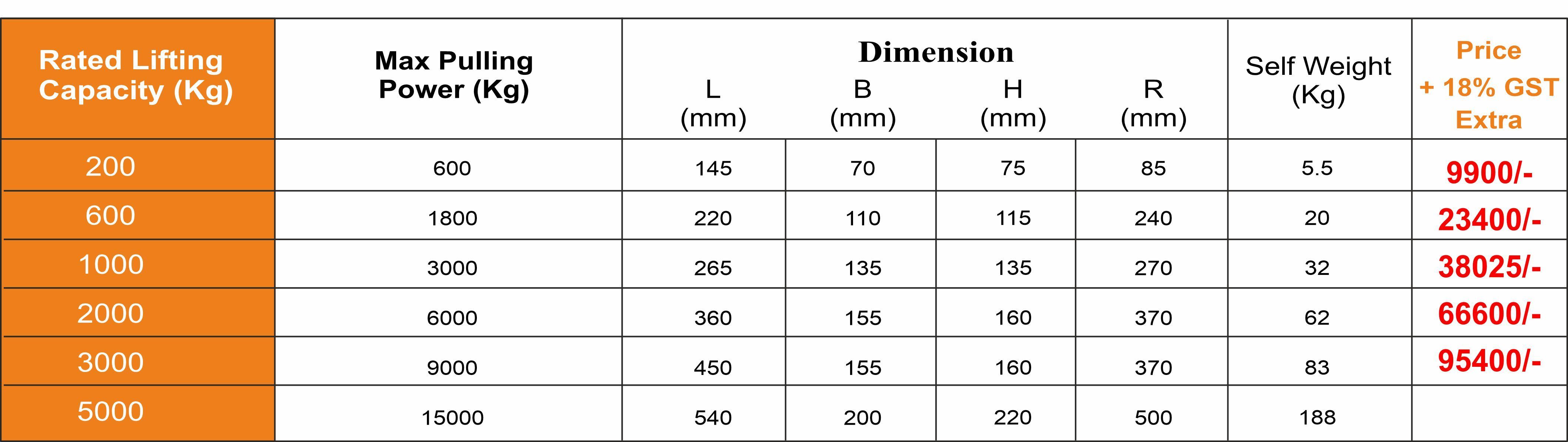

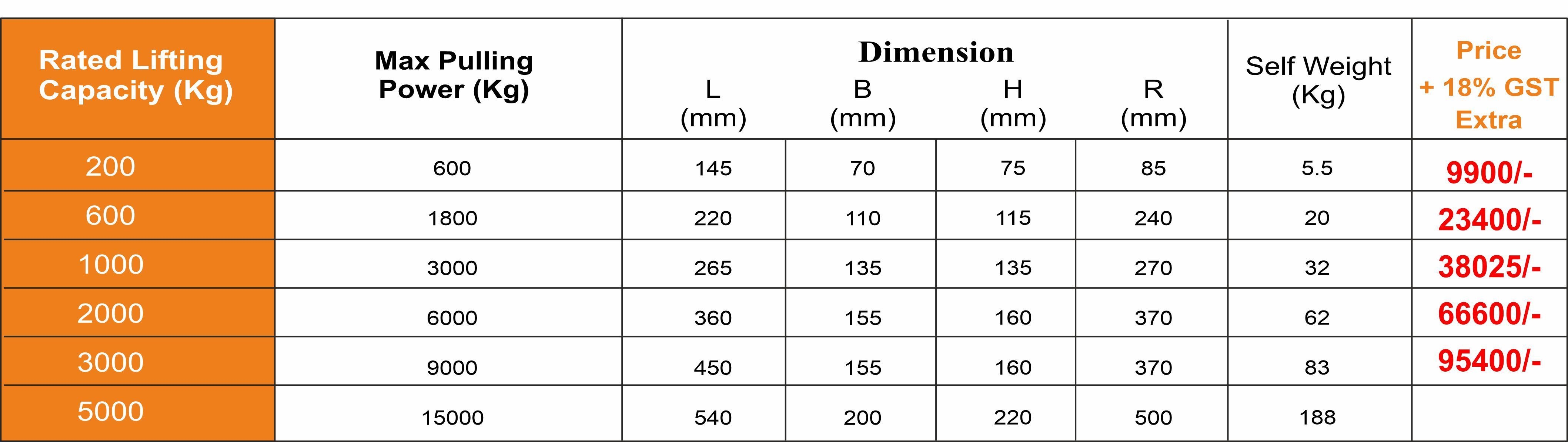

Dimension and Specification

Model - LIFTIT Permanent Magnetic Lifter

Lifting Capacity - 200 Kg

Max Pulling Power - 600 Kg

Self weight - 5.5 Kg

L - 145 MM

B - 70 MM

H - 75 MM

R - 85 MM

Other Products in 'LIFTIT Permanent Magnetic Lifter' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |