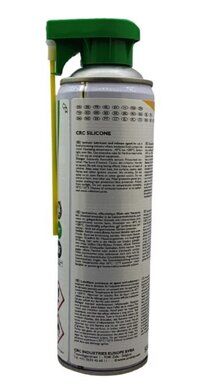

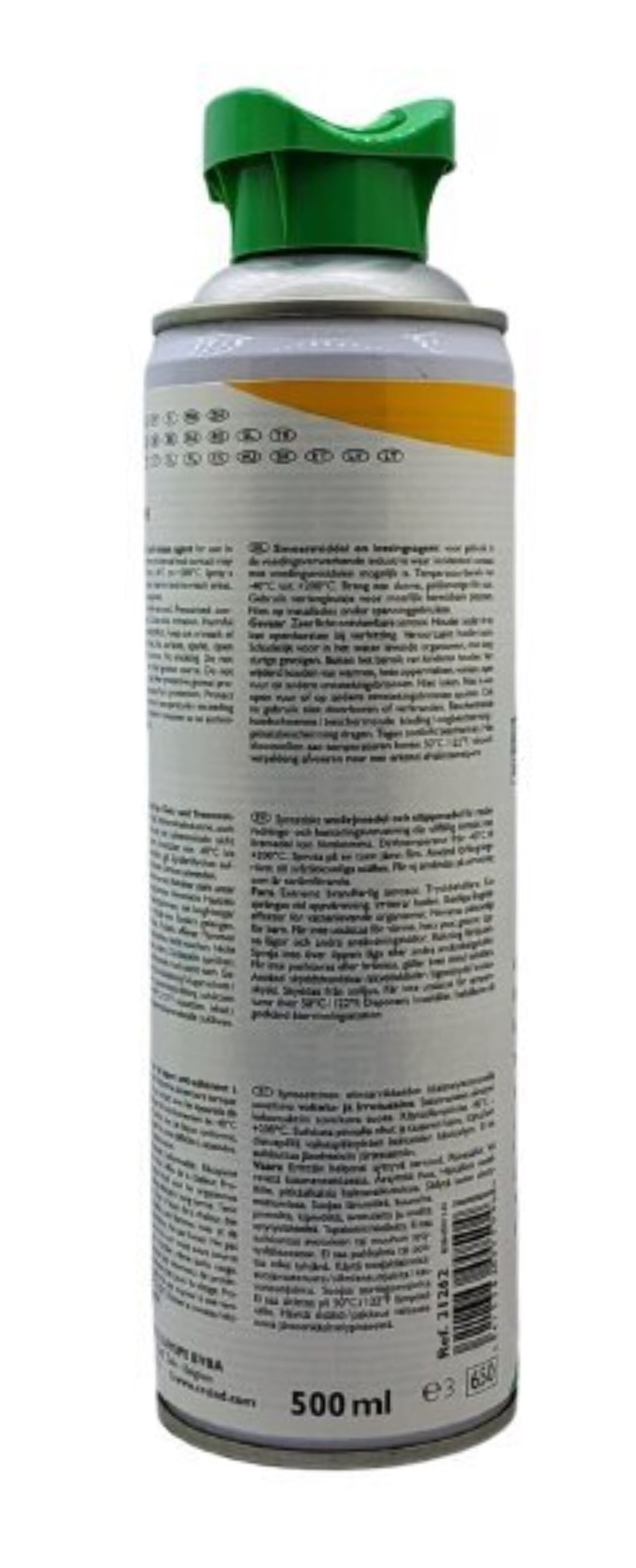

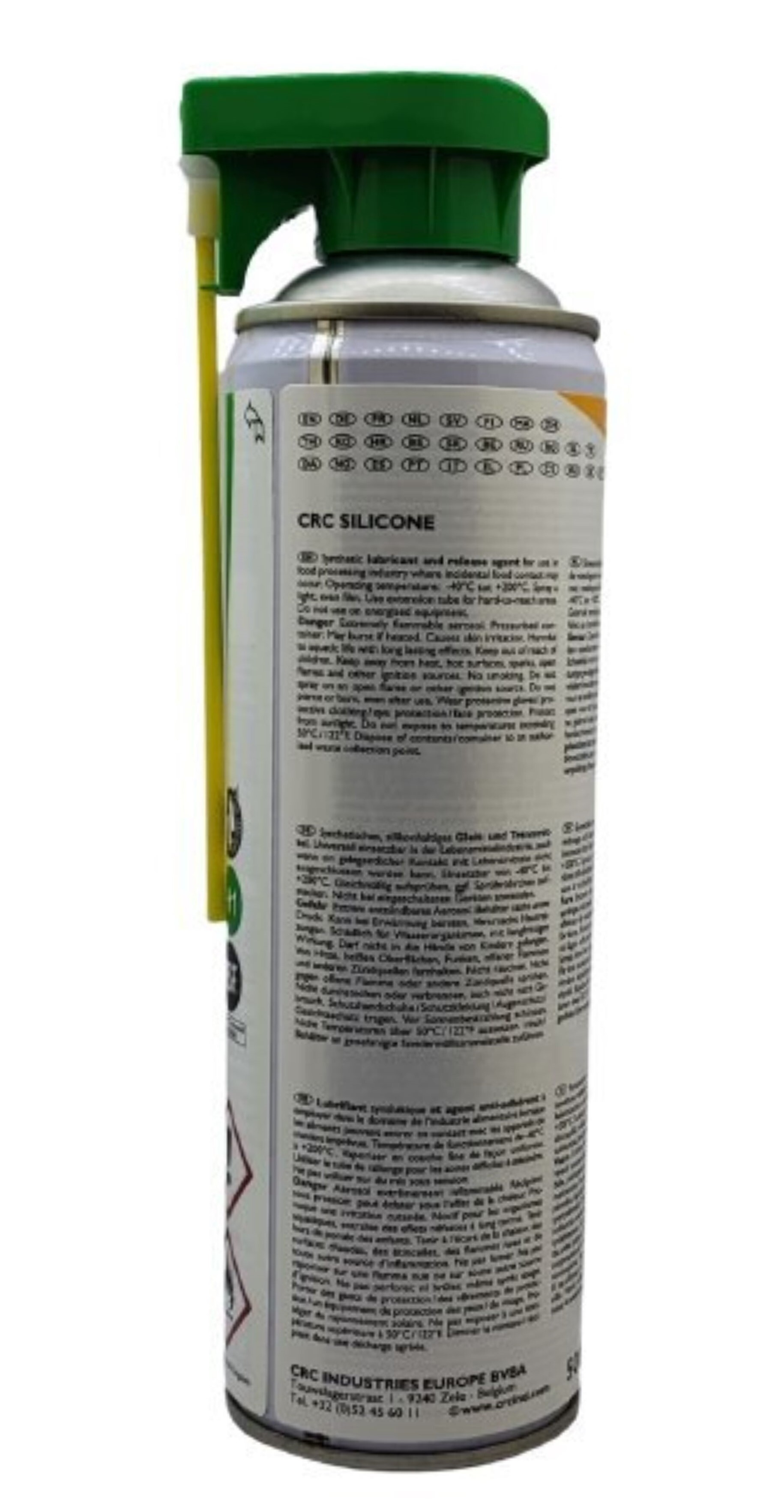

CRC सिलिकॉन फूड ग्रेड लूब्रिकेंट

उत्पाद विवरण:

- प्रॉडक्ट टाइप एरोसोल के डिब्बे

- उत्पाद प्रपत्र स्प्रे

- शेप गोल

- एप्लीकेशन अन्य

- अधिक देखने के लिए क्लिक करें

CRC सिलिकॉन फूड ग्रेड लूब्रिकेंट मूल्य और मात्रा

- बोतल/बोतल

- 12

- बोतल/बोतल

CRC सिलिकॉन फूड ग्रेड लूब्रिकेंट उत्पाद की विशेषताएं

- स्प्रे

- एरोसोल के डिब्बे

- अन्य

- गोल

CRC सिलिकॉन फूड ग्रेड लूब्रिकेंट व्यापार सूचना

- मुंबई

- कैश ऑन डिलीवरी (COD) डिलिवरी पॉइंट (DP) कैश एडवांस (CA) कैश इन एडवांस (CID) चेक

- यदि आदेश की पुष्टि हो जाती है तो हम नमूना लागत की प्रतिपूर्ति करेंगे

उत्पाद वर्णन

CRC Food Grade Silicone Spray

GENERAL DESCRIPTION

Synthetic lubricant and release agent.

Based on a premium grade silicone fluid exhibiting superiorlubrication. CRC Silicone reduces

friction in most metal and non-metal applications.Thesilicone lubricating film meets

USDA-regulations for use in food processing applicationswhere

incidental food contact with the lubricant may occur.

FEATURES

Formulated using only food grade acceptable components.

Forms an inert, stable, non-hardening film.

Eliminates squeaking, binding and sticking of metals,plastics, rubbers and other surfaces.

Low surface tension gives better coverage and deeperpenetration.

Excellent separation and release properties.

Colourless, tasteless and odourless.

Effective over a wide temperature range.

Harmless to most rubbers and plastics (test prior to use).

Aerosols are pressurised with non-flammable CO2 , giving anactive product content of 97%.

Meets FDA-regulation CFR 21-178.3570 and is authorised by

USDA - class H1, to be used as a lubricant with incidentalfood contact.

APPLICATIONS

Lubricant for :

Food processing andhandling equipment

Chutes

Guides

Rails

Conveyors

Bottling machinery

Slicers

Ovens

Freezers

Knives and saws

Any food industrylubrication point.

Release andseparating agent

DIRECTIONS

Spray light, even film on areas requiring lubrication orprotection.

Use extension tube for hard-to-reach areas.

Repeat application if necessary.

Excess or spilled product can be removed with CRC Foodkleen.

Do not use on energised equipment.

Do not use on areas to be painted.

A safety data sheet (MSDS) according EU directive 93/112 isavailable for all CRC products.

TYPICAL PRODUCT DATA (without propellant)

USDA category : H1

Appearance : clear, water-white liquid

Specific gravity ( 20C) : 0,69

Distillation range of solvents : 55-70C

Flash point (closed cup) : 0C

Vapour density (vs. air = 1) : 3

Dry film properties

Flash point (closed cup) : 300C

Pour point : -40C

Temperature range : -40 to +200C

Long term stability temperature (in air) : 150C

Surface tension : 21 mN/m

Dielectric strength : 35 kV

Viscosity (20C) : 12.500 mPa.s

PACKAGING

aerosol : 12 x 400 mlCRC Food Grade Silicone Spray

GENERAL DESCRIPTION

Synthetic lubricant and release agent.

Based on a premium grade silicone fluid exhibiting superiorlubrication. CRC Silicone reduces

friction in most metal and non-metal applications.Thesilicone lubricating film meets

USDA-regulations for use in food processing applicationswhere

incidental food contact with the lubricant may occur.

FEATURES

Formulated using only food grade acceptable components.

Forms an inert, stable, non-hardening film.

Eliminates squeaking, binding and sticking of metals,plastics, rubbers and other surfaces.

Low surface tension gives better coverage and deeperpenetration.

Excellent separation and release properties.

Colourless, tasteless and odourless.

Effective over a wide temperature range.

Harmless to most rubbers and plastics (test prior to use).

Aerosols are pressurised with non-flammable CO2 , giving anactive product content of 97%.

Meets FDA-regulation CFR 21-178.3570 and is authorised by

USDA - class H1, to be used as a lubricant with incidentalfood contact.

APPLICATIONS

Lubricant for :

Food processing andhandling equipment

Chutes

Guides

Rails

Conveyors

Bottling machinery

Slicers

Ovens

Freezers

Knives and saws

Any food industrylubrication point.

Release andseparating agent

DIRECTIONS

Spray light, even film on areas requiring lubrication orprotection.

Use extension tube for hard-to-reach areas.

Repeat application if necessary.

Excess or spilled product can be removed with CRC Foodkleen.

Do not use on energised equipment.

Do not use on areas to be painted.

A safety data sheet (MSDS) according EU directive 93/112 isavailable for all CRC products.

TYPICAL PRODUCT DATA (without propellant)

USDA category : H1

Appearance : clear, water-white liquid

Specific gravity ( 20C) : 0,69

Distillation range of solvents : 55-70C

Flash point (closed cup) : 0C

Vapour density (vs. air = 1) : 3

Dry film properties

Flash point (closed cup) : 300C

Pour point : -40C

Temperature range : -40 to +200C

GENERAL DESCRIPTION

Synthetic lubricant and release agent.

Based on a premium grade silicone fluid exhibiting superiorlubrication. CRC Silicone reduces

friction in most metal and non-metal applications.Thesilicone lubricating film meets

USDA-regulations for use in food processing applicationswhere

incidental food contact with the lubricant may occur.

FEATURES

Formulated using only food grade acceptable components.

Forms an inert, stable, non-hardening film.

Eliminates squeaking, binding and sticking of metals,plastics, rubbers and other surfaces.

Low surface tension gives better coverage and deeperpenetration.

Excellent separation and release properties.

Colourless, tasteless and odourless.

Effective over a wide temperature range.

Harmless to most rubbers and plastics (test prior to use).

Aerosols are pressurised with non-flammable CO2 , giving anactive product content of 97%.

Meets FDA-regulation CFR 21-178.3570 and is authorised by

USDA - class H1, to be used as a lubricant with incidentalfood contact.

APPLICATIONS

Lubricant for :

Food processing andhandling equipment

Chutes

Guides

Rails

Conveyors

Bottling machinery

Slicers

Ovens

Freezers

Knives and saws

Any food industrylubrication point.

Release andseparating agent

DIRECTIONS

Spray light, even film on areas requiring lubrication orprotection.

Use extension tube for hard-to-reach areas.

Repeat application if necessary.

Excess or spilled product can be removed with CRC Foodkleen.

Do not use on energised equipment.

Do not use on areas to be painted.

A safety data sheet (MSDS) according EU directive 93/112 isavailable for all CRC products.

TYPICAL PRODUCT DATA (without propellant)

USDA category : H1

Appearance : clear, water-white liquid

Specific gravity ( 20C) : 0,69

Distillation range of solvents : 55-70C

Flash point (closed cup) : 0C

Vapour density (vs. air = 1) : 3

Dry film properties

Flash point (closed cup) : 300C

Pour point : -40C

Temperature range : -40 to +200C

Long term stability temperature (in air) : 150C

Surface tension : 21 mN/m

Dielectric strength : 35 kV

Viscosity (20C) : 12.500 mPa.s

PACKAGING

aerosol : 12 x 400 mlCRC Food Grade Silicone Spray

GENERAL DESCRIPTION

Synthetic lubricant and release agent.

Based on a premium grade silicone fluid exhibiting superiorlubrication. CRC Silicone reduces

friction in most metal and non-metal applications.Thesilicone lubricating film meets

USDA-regulations for use in food processing applicationswhere

incidental food contact with the lubricant may occur.

FEATURES

Formulated using only food grade acceptable components.

Forms an inert, stable, non-hardening film.

Eliminates squeaking, binding and sticking of metals,plastics, rubbers and other surfaces.

Low surface tension gives better coverage and deeperpenetration.

Excellent separation and release properties.

Colourless, tasteless and odourless.

Effective over a wide temperature range.

Harmless to most rubbers and plastics (test prior to use).

Aerosols are pressurised with non-flammable CO2 , giving anactive product content of 97%.

Meets FDA-regulation CFR 21-178.3570 and is authorised by

USDA - class H1, to be used as a lubricant with incidentalfood contact.

APPLICATIONS

Lubricant for :

Food processing andhandling equipment

Chutes

Guides

Rails

Conveyors

Bottling machinery

Slicers

Ovens

Freezers

Knives and saws

Any food industrylubrication point.

Release andseparating agent

DIRECTIONS

Spray light, even film on areas requiring lubrication orprotection.

Use extension tube for hard-to-reach areas.

Repeat application if necessary.

Excess or spilled product can be removed with CRC Foodkleen.

Do not use on energised equipment.

Do not use on areas to be painted.

A safety data sheet (MSDS) according EU directive 93/112 isavailable for all CRC products.

TYPICAL PRODUCT DATA (without propellant)

USDA category : H1

Appearance : clear, water-white liquid

Specific gravity ( 20C) : 0,69

Distillation range of solvents : 55-70C

Flash point (closed cup) : 0C

Vapour density (vs. air = 1) : 3

Dry film properties

Flash point (closed cup) : 300C

Pour point : -40C

Temperature range : -40 to +200C

Long term stability temperature (in air) : 150C

Surface tension : 21 mN/m

Dielectric strength : 35 kV

Viscosity (20C) : 12.500 mPa.s

PACKAGING

aerosol : 12 x 400 mlCRC Food Grade Silicone Spray

GENERAL DESCRIPTION

Synthetic lubricant and release agent.

Based on a premium grade silicone fluid exhibiting superiorlubrication. CRC Silicone reduces

friction in most metal and non-metal applications.Thesilicone lubricating film meets

USDA-regulations for use in food processing applicationswhere

incidental food contact with the lubricant may occur.

FEATURES

Formulated using only food grade acceptable components.

Forms an inert, stable, non-hardening film.

Eliminates squeaking, binding and sticking of metals,plastics, rubbers and other surfaces.

Low surface tension gives better coverage and deeperpenetration.

Excellent separation and release properties.

Colourless, tasteless and odourless.

Effective over a wide temperature range.

Harmless to most rubbers and plastics (test prior to use).

Aerosols are pressurised with non-flammable CO2 , giving anactive product content of 97%.

Meets FDA-regulation CFR 21-178.3570 and is authorised by

USDA - class H1, to be used as a lubricant with incidentalfood contact.

APPLICATIONS

Lubricant for :

Food processing andhandling equipment

Chutes

Guides

Rails

Conveyors

Bottling machinery

Slicers

Ovens

Freezers

Knives and saws

Any food industrylubrication point.

Release andseparating agent

DIRECTIONS

Spray light, even film on areas requiring lubrication orprotection.

Use extension tube for hard-to-reach areas.

Repeat application if necessary.

Excess or spilled product can be removed with CRC Foodkleen.

Do not use on energised equipment.

Do not use on areas to be painted.

A safety data sheet (MSDS) according EU directive 93/112 isavailable for all CRC products.

TYPICAL PRODUCT DATA (without propellant)

USDA category : H1

Appearance : clear, water-white liquid

Specific gravity ( 20C) : 0,69

Distillation range of solvents : 55-70C

Flash point (closed cup) : 0C

Vapour density (vs. air = 1) : 3

Dry film properties

Flash point (closed cup) : 300C

Pour point : -40C

Temperature range : -40 to +200C

Long term stability temperature (in air) : 150C

Surface tension : 21 mN/m

Dielectric strength : 35 kV

Viscosity (20C) : 12.500 mPa.s

PACKAGING

aerosol : 12 x 400 mlCRC Food Grade Silicone Spray

GENERAL DESCRIPTION

Synthetic lubricant and release agent.

Based on a premium grade silicone fluid exhibiting superiorlubrication. CRC Silicone reduces

friction in most metal and non-metal applications.Thesilicone lubricating film meets

USDA-regulations for use in food processing applicationswhere

incidental food contact with the lubricant may occur.

FEATURES

Formulated using only food grade acceptable components.

Forms an inert, stable, non-hardening film.

Eliminates squeaking, binding and sticking of metals,plastics, rubbers and other surfaces.

Low surface tension gives better coverage and deeperpenetration.

Excellent separation and release properties.

Colourless, tasteless and odourless.

Effective over a wide temperature range.

Harmless to most rubbers and plastics (test prior to use).

Aerosols are pressurised with non-flammable CO2 , giving anactive product content of 97%.

Meets FDA-regulation CFR 21-178.3570 and is authorised by

USDA - class H1, to be used as a lubricant with incidentalfood contact.

APPLICATIONS

Lubricant for :

Food processing andhandling equipment

Chutes

Guides

Rails

Conveyors

Bottling machinery

Slicers

Ovens

Freezers

Knives and saws

Any food industrylubrication point.

Release andseparating agent

DIRECTIONS

Spray light, even film on areas requiring lubrication orprotection.

Use extension tube for hard-to-reach areas.

Repeat application if necessary.

Excess or spilled product can be removed with CRC Foodkleen.

Do not use on energised equipment.

Do not use on areas to be painted.

A safety data sheet (MSDS) according EU directive 93/112 isavailable for all CRC products.

TYPICAL PRODUCT DATA (without propellant)

USDA category : H1

Appearance : clear, water-white liquid

Specific gravity ( 20C) : 0,69

Distillation range of solvents : 55-70C

Flash point (closed cup) : 0C

Vapour density (vs. air = 1) : 3

Dry film properties

Flash point (closed cup) : 300C

Pour point : -40C

Temperature range : -40 to +200C

Long term stability temperature (in air) : 150C

Surface tension : 21 mN/m

Dielectric strength : 35 kV

Viscosity (20C) : 12.500 mPa.s

PACKAGING

aerosol : 12 x 400 ml

Long term stability temperature (in air) : 150C

Surface tension : 21 mN/m

Dielectric strength : 35 kV

Viscosity (20C) : 12.500 mPa.s

PACKAGING

aerosol : 12 x 400 ml

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

सीआरसी सफाई स्प्रे अन्य उत्पाद

|

JAY AGENCIEZ

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |