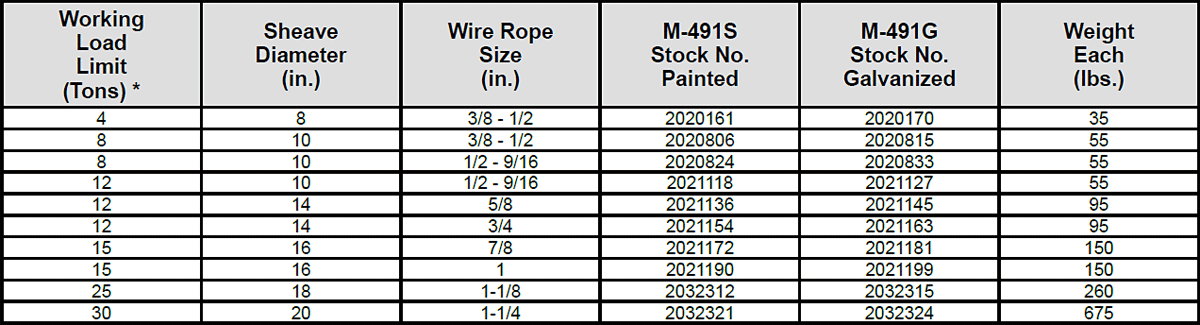

Mckissick M 491 G Tower Derrick Oilfield Servicing Hoist Blocks

Product Details:

- Product Type Industrial

- Condition New

- Lifting Capacity 4 Ton to 15 Ton Tonne

- Click to View more

Mckissick M 491 G Tower Derrick Oilfield Servicing Hoist Blocks Price And Quantity

- 10 Piece

- 9999 INR/Piece

- 9999.00 - 9999.00 INR/Piece

Mckissick M 491 G Tower Derrick Oilfield Servicing Hoist Blocks Product Specifications

- Industrial

- New

- 4 Ton to 15 Ton Tonne

Mckissick M 491 G Tower Derrick Oilfield Servicing Hoist Blocks Trade Information

- Mumbai

- Cash Against Delivery (CAD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 12 Piece Per Month

- 1 Week

- Box Pack

- Asia Australia Africa Central America North America South America Eastern Europe Western Europe Middle East

- All India

- Gov. Approved Certificate

Product Description

Product description

The new design offers the reliability of standard McKissick folding blocks, making this series the ideal choice for heavy-duty applications, such as use on tugger winches or rigging.

- Galvanized surface.

- Blocks of 203 mm and 254 mm are suitable for two rope gauges.

- Swivels, connectors, hook bearings and shackles made of hardened and tempered forged steel.

- Easy maintenance thanks to rope sheave lubrication via centrally mounted nipple.

- Safety factor of 4:1.

- All blocks 356 mm and larger feature McKissick Roll Forgedï sheaves with flame-hardened groove.

- Recessed side sections reduce the gap between the sheave rim and side section, so the sheave will not fall out of the block even if the center pin is lost.

- Encapsulated tapered sheave bearings increase pin and bearing life. At the same time, this allows higher rope speeds than with conventional folding blocks.

- Easy positioning due to swivel shackles.

- Suitable for passenger transport provided all personnel, including the winch operator, have been trained to follow all applicable national, local and industry guidelines.

1.) Applications on tugs/load cranes: API RP54

2.) Applications on rigs: OSHA Directive CPL 2-1.36

- Openings in side panels for attachment of a second device to secure block.

- Manufactured in a factory certified to API Q1.

- Type approved and certified in accordance with ABS 2006 Steel Vessel

Rules 1-1-17.7 (Regulations for Steel Vessels) and ABS Guide for Certification of Cranes.

- All sizes equipped with RFID.

* Ultimate Load is 4 times the Working Load Limit.

Other Products in 'Crosby' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |